HIPS and ABS Plastic Sheet Production Process

1. Raw Material Preparation and Drying

The production process begins with the preparation of HIPS and ABS granules. These granules are dried in dehumidifying ovens before production. Especially ABS material, if processed in a moist environment, can suffer surface quality deterioration. Therefore, the drying step is critical to maintain product quality.

2. Extrusion

The dried granules are melted in single-screw or co-extruder machines. In these machines, the material is heated to a molten state and homogenously mixed by the screw system. The resulting melt is filtered to remove foreign particles. During this stage, the melt pump controls the pressure and flow of the molten material to ensure even distribution into the die.

3. Molding (T-Die)

The molten material is formed into a sheet by passing through a specialized die called a T-Die. This die ensures the desired width and thickness. The design of the T-Die is crucial for surface quality and thickness uniformity.

4. Calendaring (Three-Roll Calendar)

The hot sheet from the die is directed to a three-roll calendar system. This system adjusts the sheet to the desired thickness and applies surface textures. Various patterns—sand grain, leather, luggage textures—are imparted via the rollers. Specialized rollers are used to achieve glossy surfaces.

5. Cooling and Cutting

After embossing, the sheet is cooled in cooling units to stabilize it. It is then cut to size and stacked for packaging. Edges are trimmed and surface quality is inspected at this stage.

Product Features and Applications

HIPS Sheets

-

Impact Resistance: HIPS sheets have high impact strength, making them suitable for applications requiring mechanical durability.

-

Machinability: Their easy workability allows for cutting, drilling, and shaping processes without difficulty.

-

Applications: Commonly used in white goods interior panels, toys, packaging materials, and automotive interior trim.

ABS Sheets

-

Surface Quality: Noted for its glossy and aesthetically pleasing surface.

-

Mechanical Properties: Exhibits high impact resistance and rigidity.

-

Applications: Preferred for automotive parts, electronic device enclosures, luggage and suitcase manufacturing.

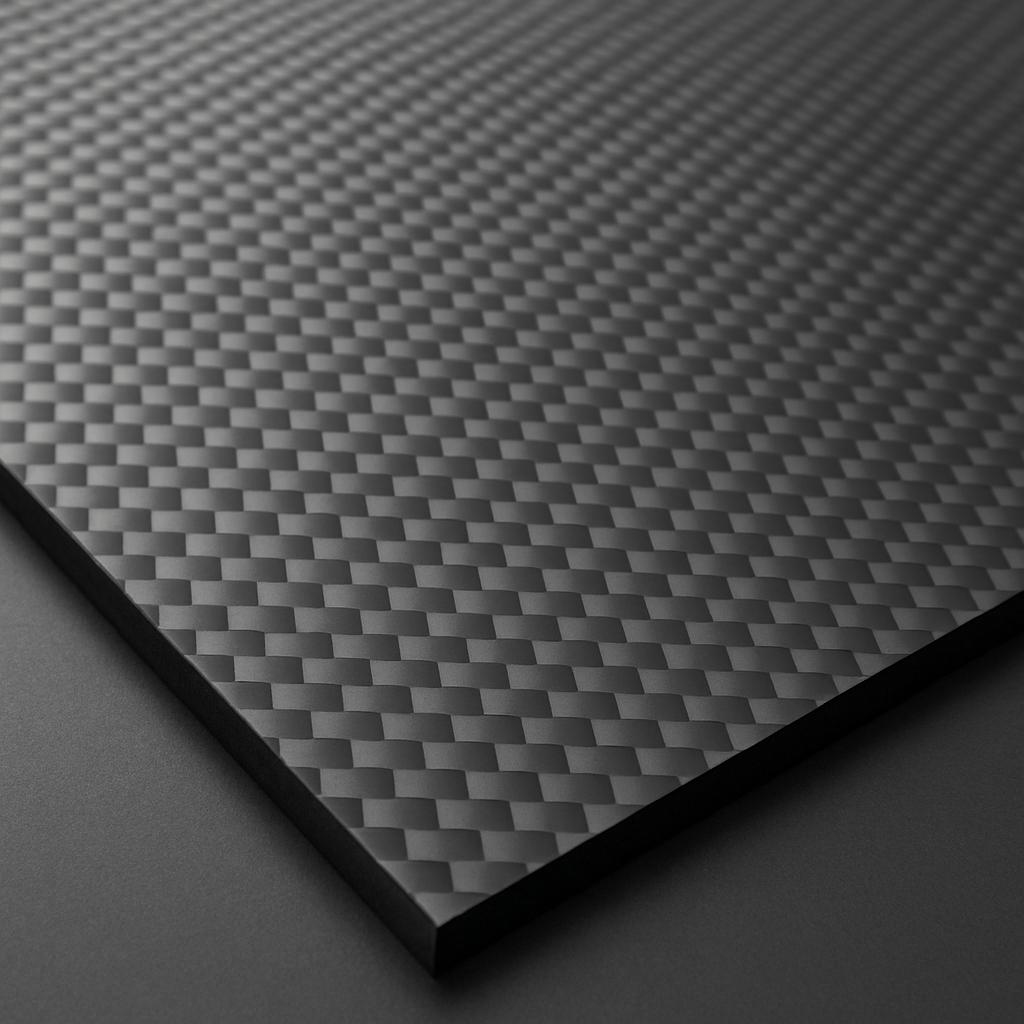

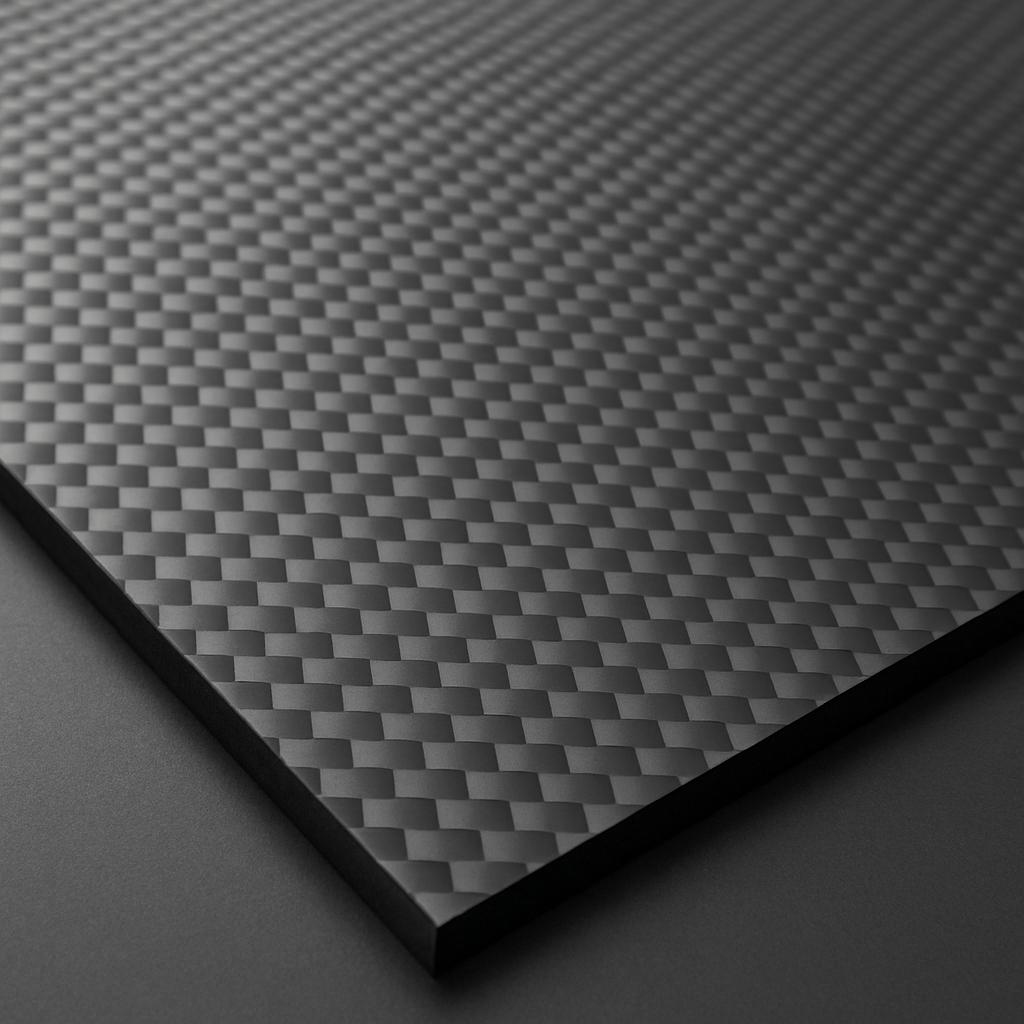

Carbon Texture

Sand Texture

Leather Texture

Infinite Color and Pattern Options

HIPS and ABS sheets can be customized with a wide range of colors and surface patterns according to customer requirements. Options such as sand, leather, and luggage textures enhance the aesthetic and functional properties of the products. Glossy sheets are especially favored in applications requiring visual appeal.