ABS Thermoforming Solutions for the Automotive Industry

Durable, Lightweight, and Aesthetic Production Technology

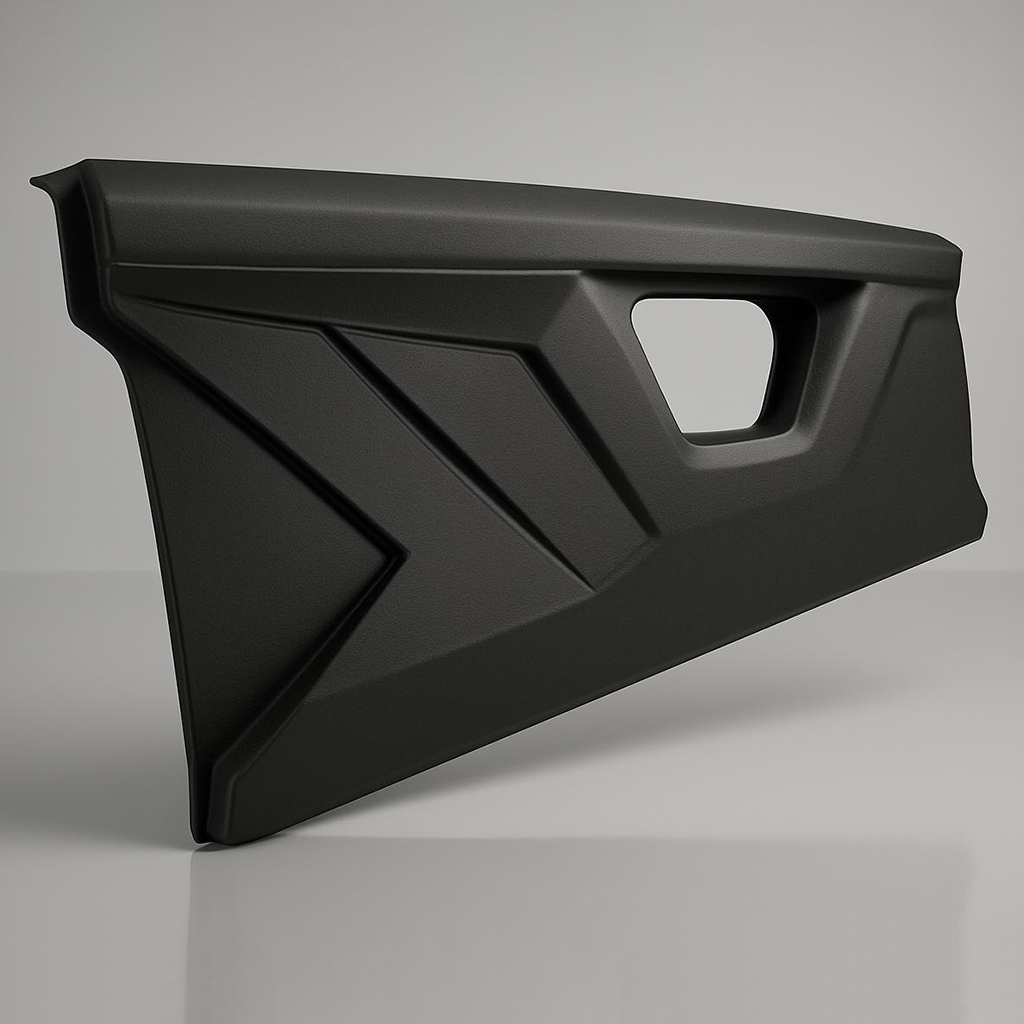

Plastic parts used in the automotive industry must meet high standards both functionally and aesthetically. At Formic Plastik, we offer industry-specific, reliable, and efficient solutions with parts produced from ABS (Acrylonitrile Butadiene Styrene) material using the vacuum thermoforming method.

Application Areas

Our ABS thermoformed products are widely used in the automotive sector in the following areas:

-

Vehicle interior trim panels

-

Instrument and control panel housings

-

Door interior coverings

-

Trunk interior surface elements

-

Exterior protective and decorative plastic components

Technical and Operational Advantages

-

High Impact Resistance and Lightness: The mechanical strength and low density of ABS material contribute to vehicle performance.

-

Surface Quality and Aesthetic Appearance: Smooth surfaces obtained through the thermoforming technique are suitable for painting and coating applications.

-

Fast Production and Low Molding Cost: The vacuum thermoforming method offers significant time and cost advantages, especially in small and medium-scale productions.

-

Design Flexibility: Easily adaptable to complex geometries and special project needs.

Formic Plastik Quality and Assurance

Our fundamental principle is to produce long-lasting products that meet customer expectations and comply with industry standards. With our extensive machine park, experienced technical team, and flexible production capacity, we provide tailor-made solutions for your automotive projects. Formic Plastik is your reliable partner in all stages, from industrial design to molding, production, and quality control processes.