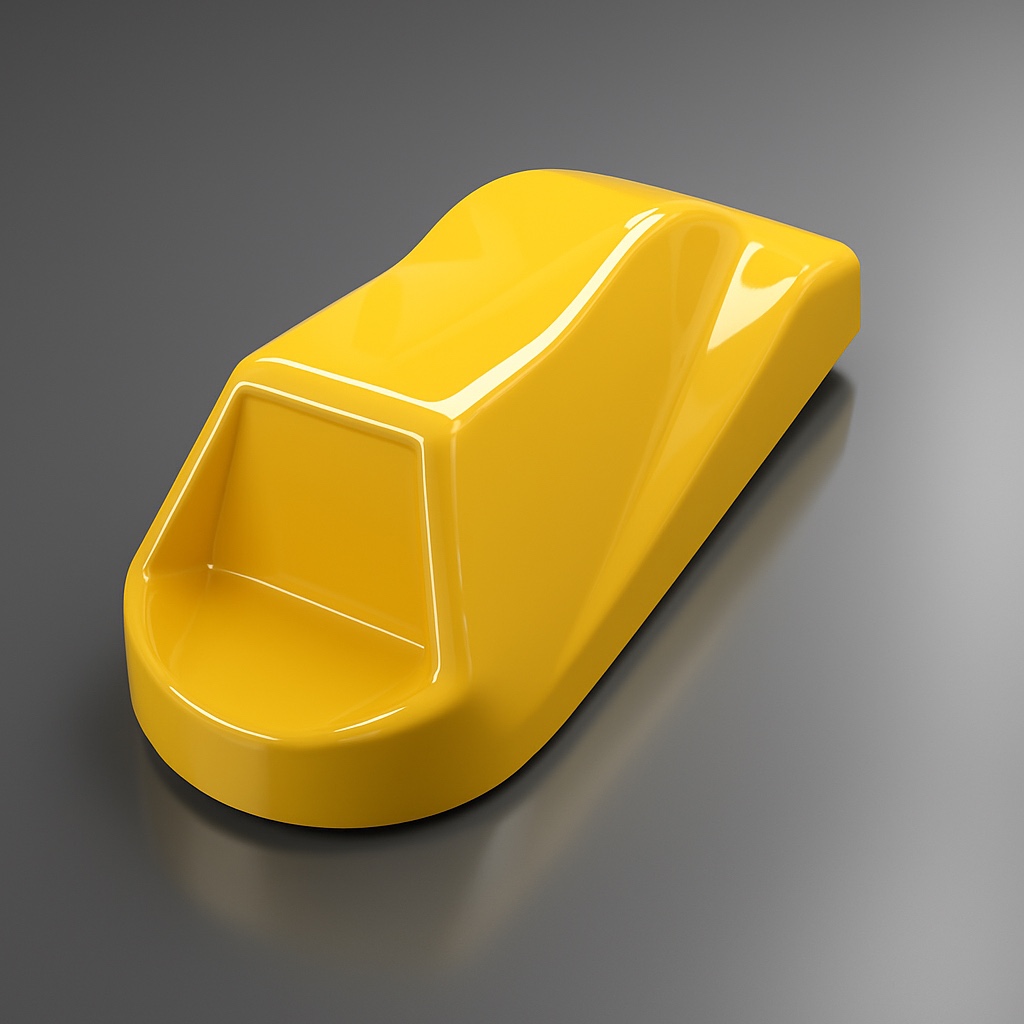

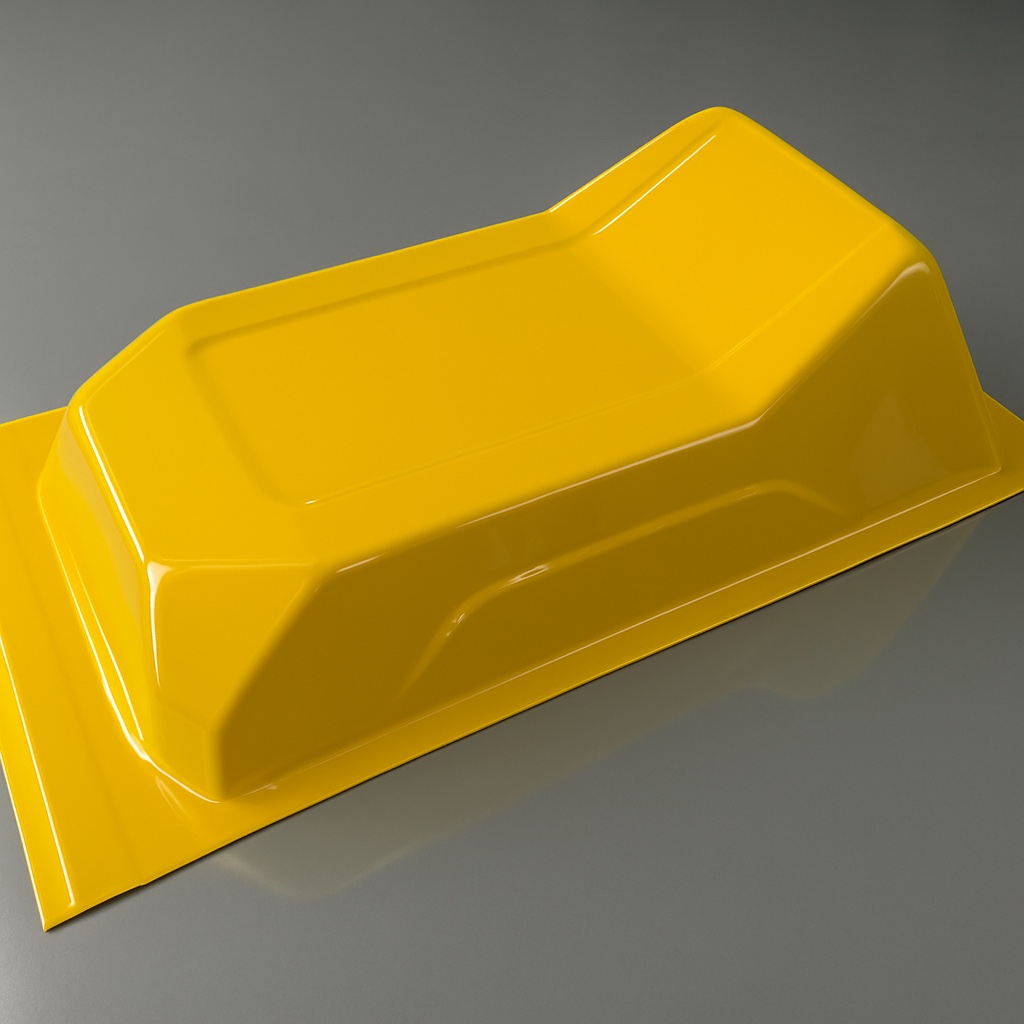

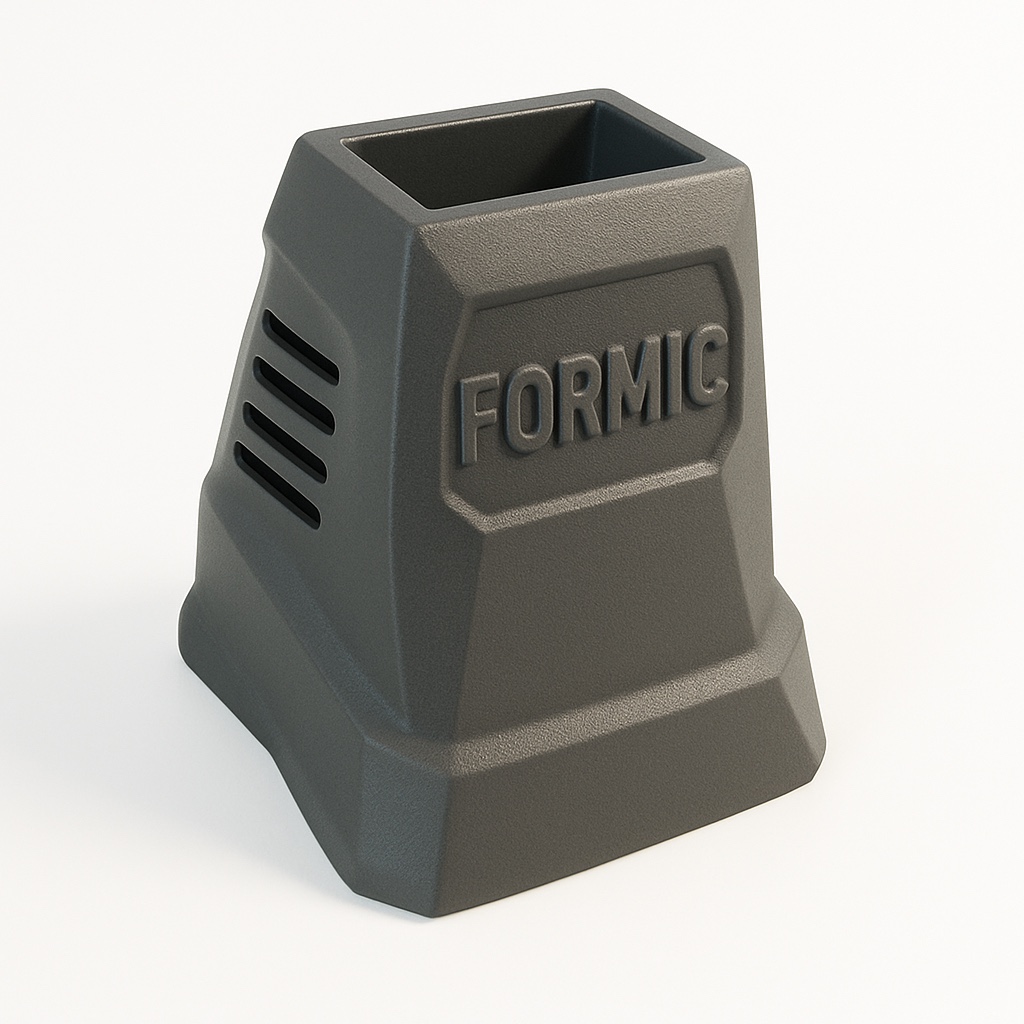

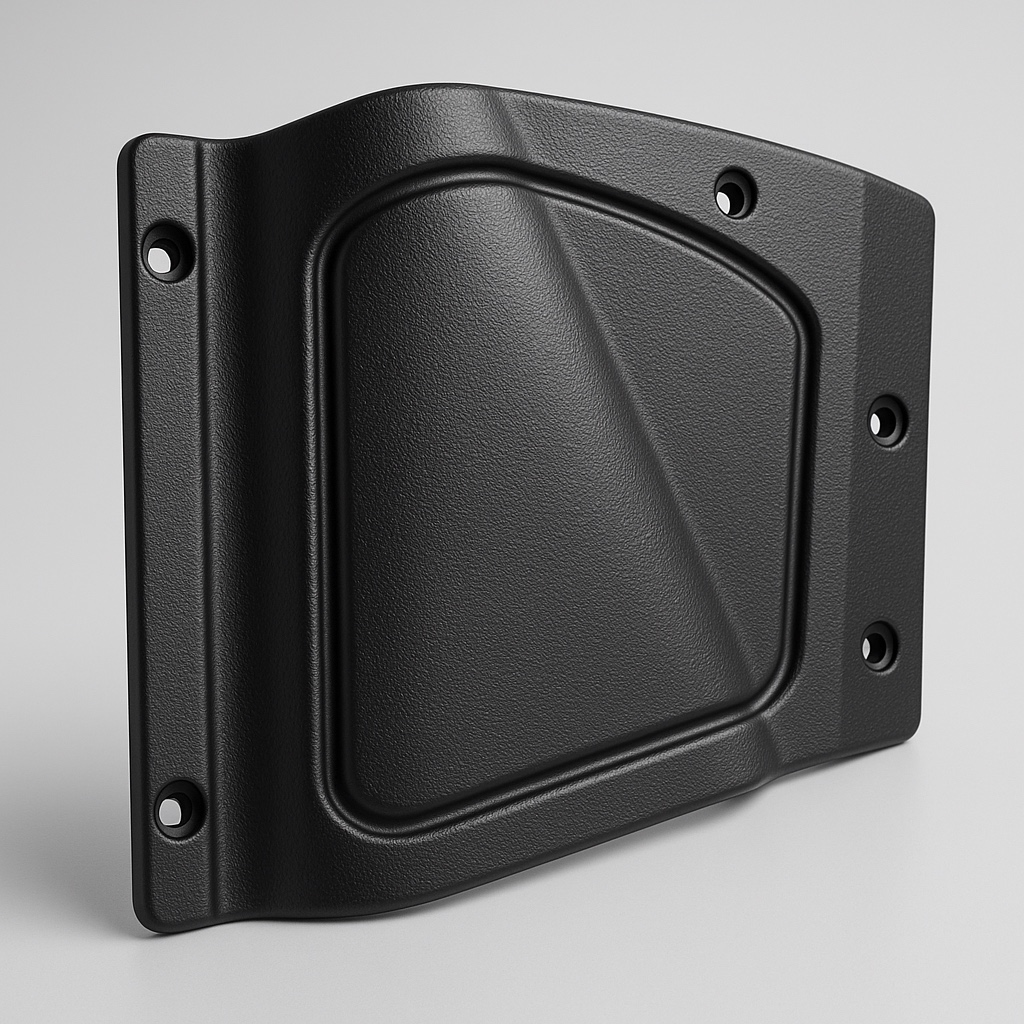

High-Performance Thermoforming Solutions for the Machinery Sector

Durability, Efficiency, and Design Flexibility with ABS and PS-Based Vacuum Forming Productions

The machinery manufacturing industry requires technical part solutions designed for heavy-duty conditions, ensuring high functionality and long service life. In this context, the ABS and PS thermoformed vacuum products developed by Formic Plastik meet the sector's expectations in both mechanical strength and production efficiency at high-quality standards.

Material-Based Technical Capabilities

ABS Thermoform Products

-

Provides maximum resistance to physical stress thanks to high impact strength.

-

Thermal stability ensures dimensional consistency across wide temperature ranges.

-

Chemical resistance offers superior durability against oils, solvents, and industrial cleaning agents.

-

UV-stabilized variants deliver long-lasting and color-stable solutions for outdoor applications.

PS Thermoform Products

-

Low specific weight facilitates operational ease during transport and assembly processes.

-

High surface aesthetics ensure smoothness and print compatibility, supporting corporate design integrity.

-

Economic production advantage allows competitive cost structures for high-volume orders.

Application Areas

Our thermoformed vacuum products for the machinery sector are used in the following areas according to functional, structural, and aesthetic needs:

-

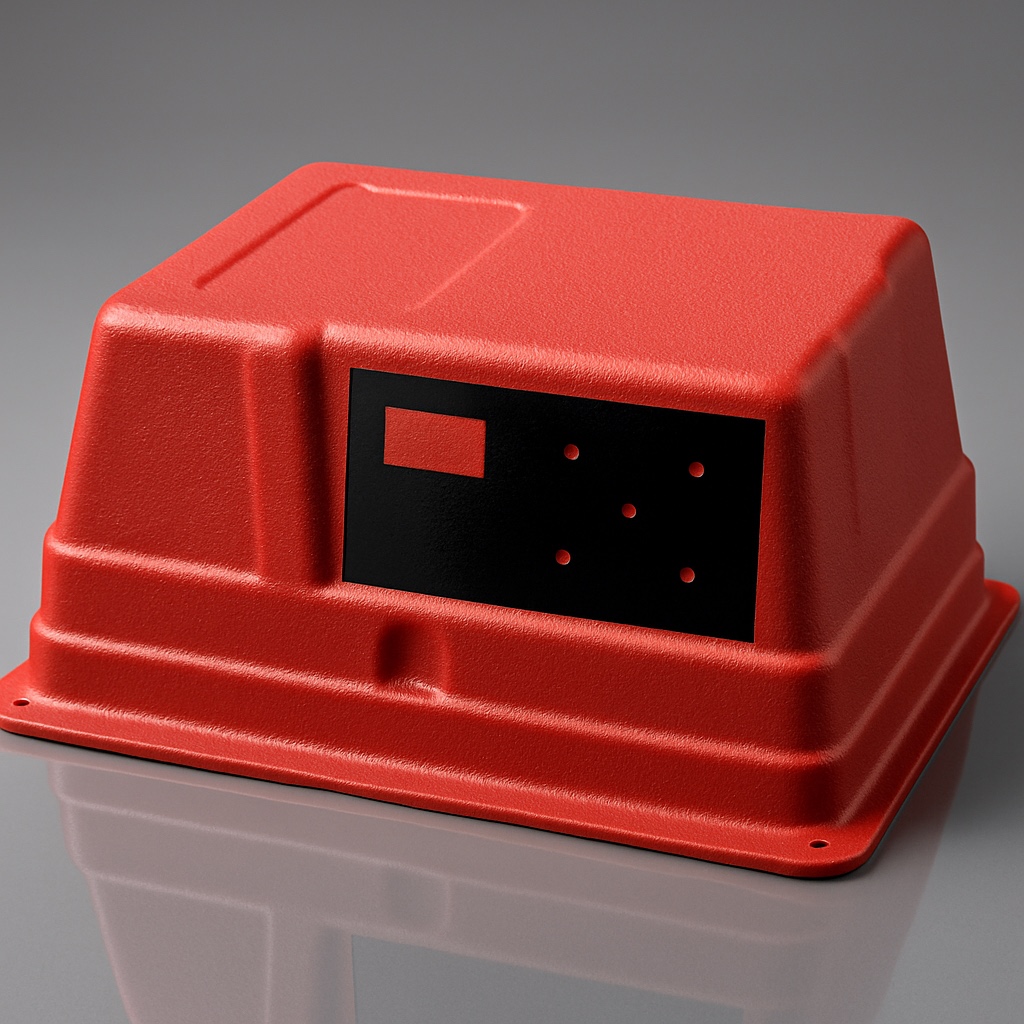

External body panels and equipment coverings

-

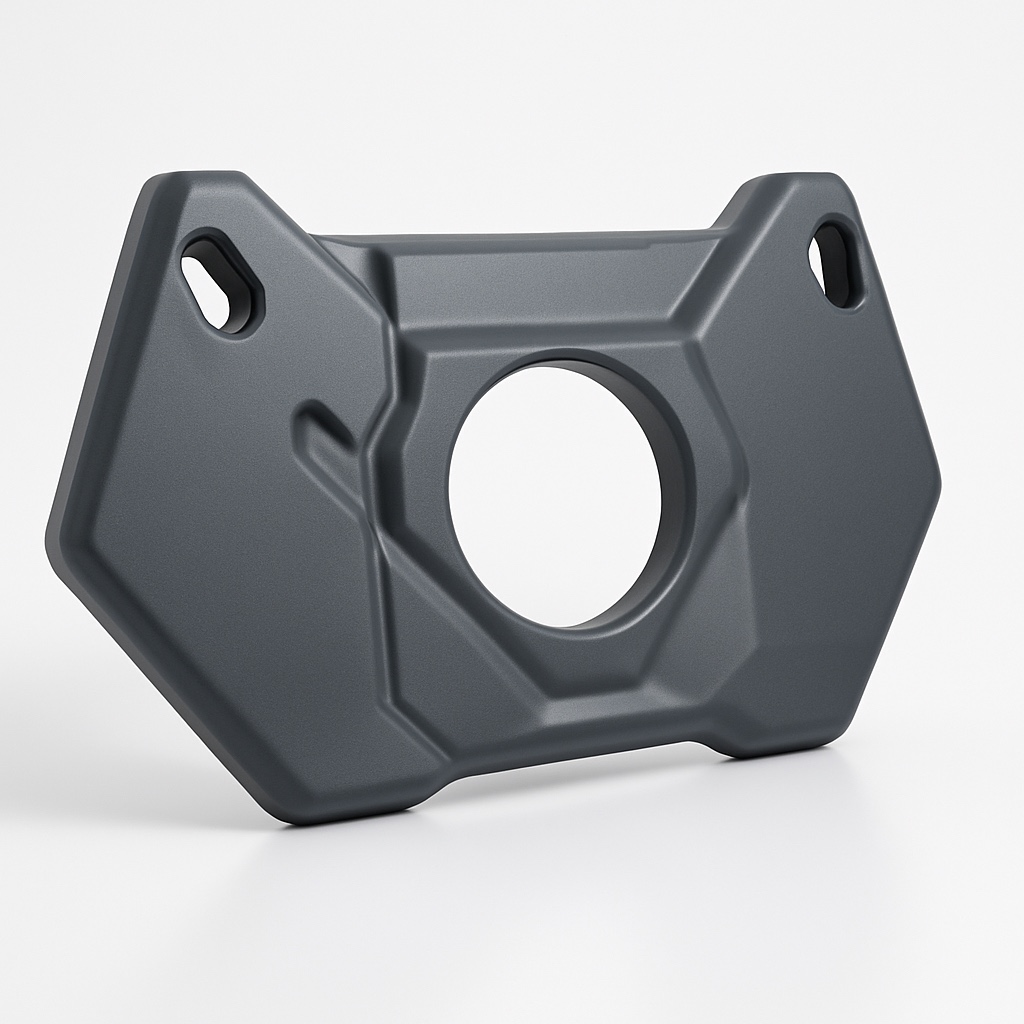

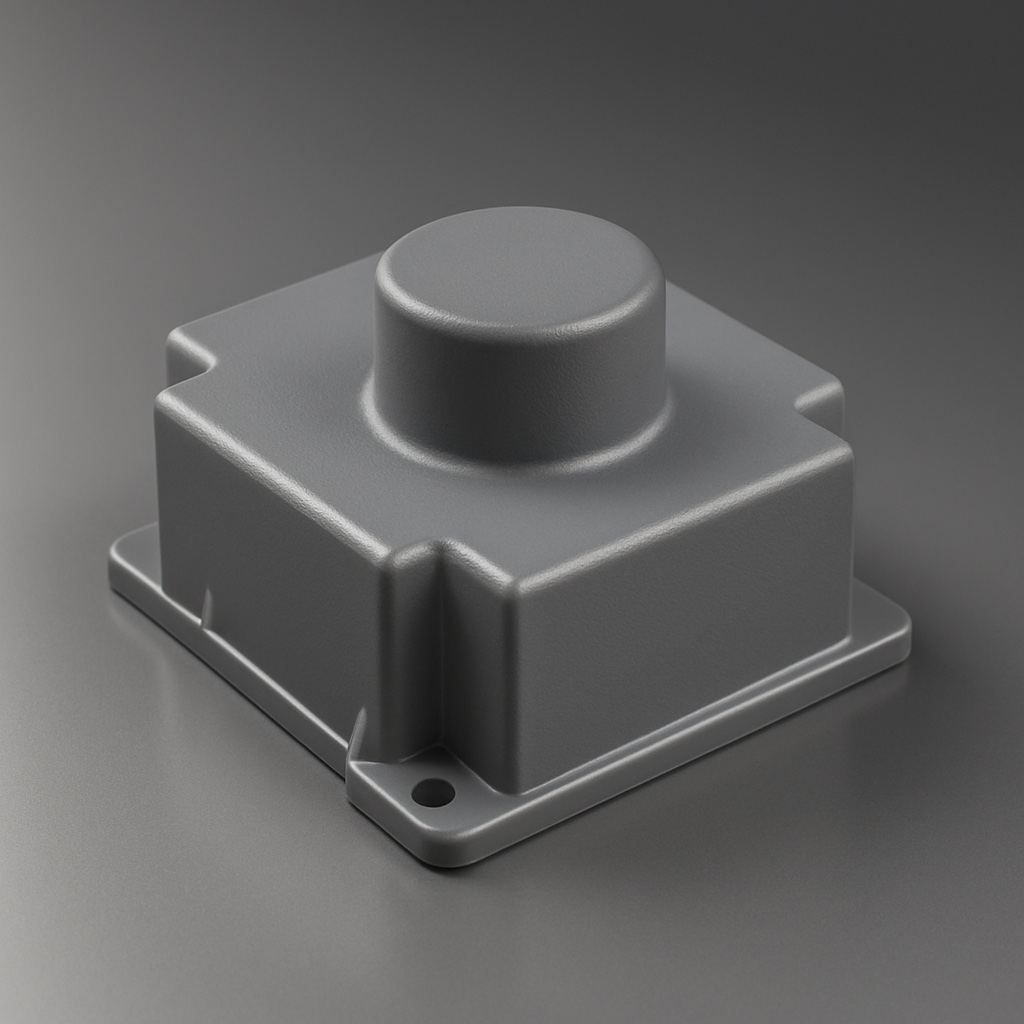

Motor, reducer, and transmission component housings

-

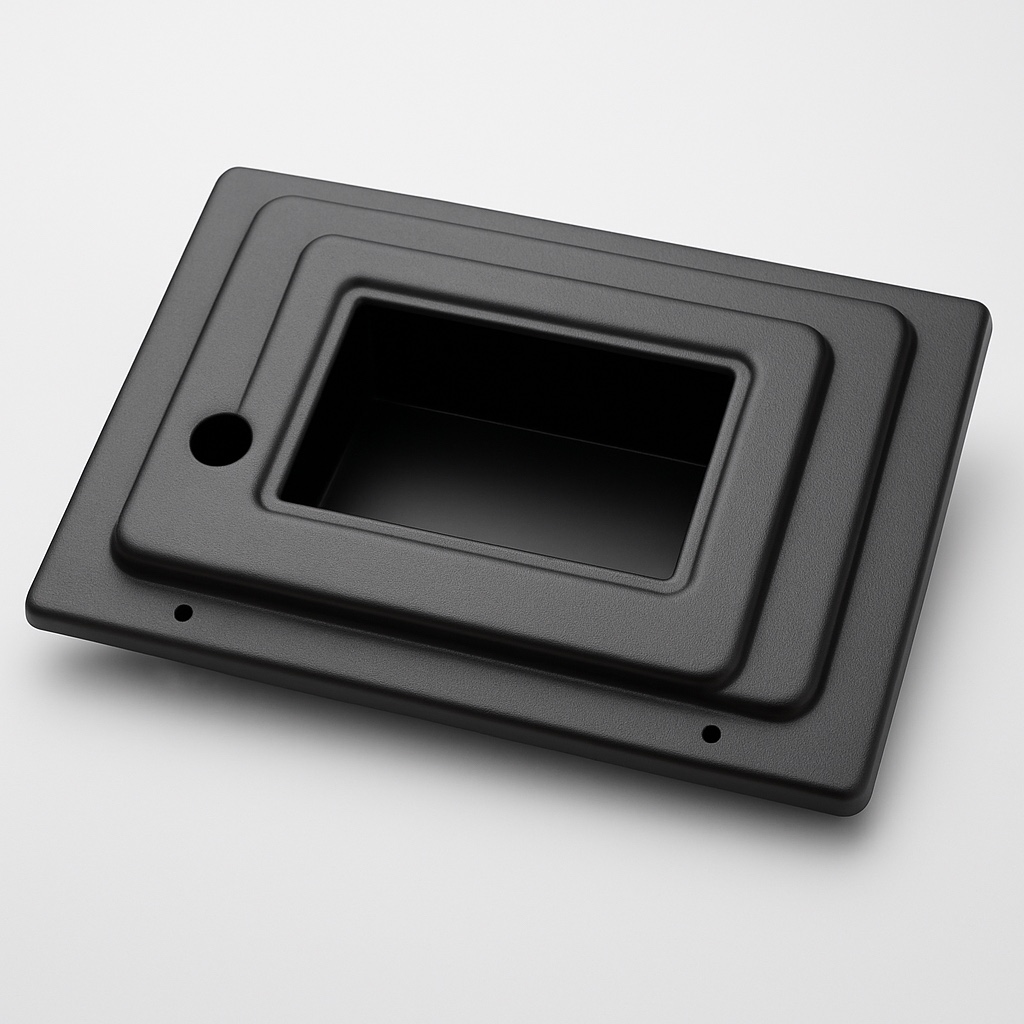

Operator panel frames and support parts

-

Internal cabin partitions and direction panels

-

Air ducts and custom protective plastic components

Strategic Advantages of Thermoforming Technology

-

Low investment cost mold systems allow rapid transition to production.

-

High design flexibility enables model-specific custom manufacturing.

-

Mass production consistency ensures dimensional and quality standards for every part.

-

Lightweight structure supports energy efficiency and logistics optimization.

Our Production Processes

Formic Plastik provides the following services to its customers with its end-to-end integrated production infrastructure:

-

CAD-supported product design and technical consultancy

-

Rapid prototyping and aluminum mold manufacturing

-

Mass production on fully automatic thermoforming lines

-

Post-processing surface finishing, quality control, and logistics planning

All our processes are carried out under ISO 9001:2015 Quality Management System assurance, in accordance with the principles of traceability and sustainability.