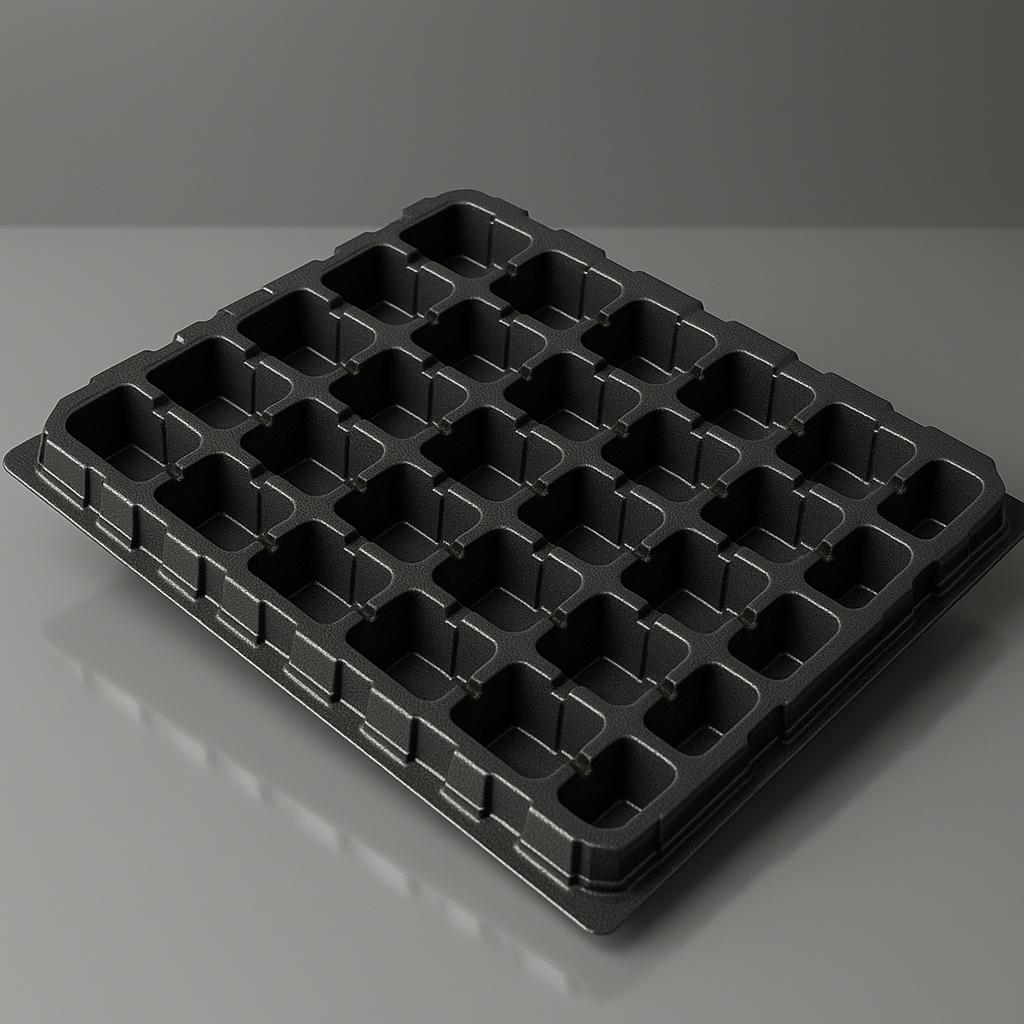

Our company aims to maximize product safety and operational efficiency with vacuum plastic separator and packaging solutions developed for manufacturers and suppliers operating in various industrial sectors. These solutions are customized according to the product’s shape, precision, and transportation conditions, and are supported by technical infrastructure to meet industry-specific needs.

Known for its high impact resistance, rigidity, and surface quality, ABS is an ideal material for the automotive and electronics industries. Its dimensional stability during thermal forming makes it suitable for producing complex shapes.

Cost-effective and highly processable, HIPS is preferred for low-cost but durable packaging needs. It is frequently used for non-food products and industrial transport separators.

Renowned for its transparency, chemical resistance, and recyclability, PET is commonly chosen for sectors where hygiene is crucial (medical and non-food hygiene products).

Optimized thickness and form structures based on raw material ensure effective protection of products against impact, vibration, and deformation.

Special molds created through 3D modeling for each product provide maximum fit, space savings, and logistical convenience.

The majority of the raw materials used are recyclable, and our eco-friendly production policies focus on waste minimization.

We manufacture custom solutions for numerous sectors including automotive, electronics, white goods, medical, defense, and spare parts, with rapid technical revisions applied according to customer requirements.

Under the Formic brand, our vacuum plastic separator and packaging systems combine technology, quality, and environmental sensitivity to deliver sustainable and value-added solutions to our customers.